Manufacturing

[vc_row][vc_column][vc_column_text]

Thompson & Redwood Manufacturing

Excellence in stock feed since 1985

[/vc_column_text][vc_single_image image=”1884″ img_size=”650×300″ alignment=”center” style=”vc_box_border”][/vc_column][/vc_row][vc_row equal_height=”yes”][vc_column width=”1/2″][vc_column_text css=”.vc_custom_1473235200814{background-color: #ffffff !important;}”]

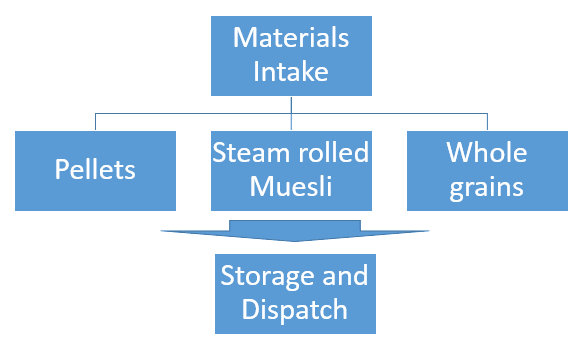

Our manufacturing process has been developed to provide high quality, fresh and consistent products. Being dedicated to animal nutrition, we use technology as a means to both develop and monitor our product quality; with the end result being an excellent nutritional solution for your animal! Our manufacturing process is as follows:

[/vc_column_text][/vc_column][vc_column width=”1/2″][vc_column_text] [/vc_column_text][/vc_column][/vc_row][vc_row css=”.vc_custom_1520935070919{margin-bottom: 60px !important;}”][vc_column width=”1/2″ css=”.vc_custom_1520935148729{margin-right: 3px !important;background-color: #efefef !important;}”][vc_row_inner][vc_column_inner][vc_column_text css=”.vc_custom_1516693218660{background-color: #efefef !important;}”]Materials Intake: Ingredients are purchased from reputable suppliers under appropriate contracts and quality standards. Bulk grains are inspected prior to delivery to ensure they meet our high standards. Vitamin/mineral premixes and other additives are purchased.

[/vc_column_text][/vc_column][/vc_row][vc_row css=”.vc_custom_1520935070919{margin-bottom: 60px !important;}”][vc_column width=”1/2″ css=”.vc_custom_1520935148729{margin-right: 3px !important;background-color: #efefef !important;}”][vc_row_inner][vc_column_inner][vc_column_text css=”.vc_custom_1516693218660{background-color: #efefef !important;}”]Materials Intake: Ingredients are purchased from reputable suppliers under appropriate contracts and quality standards. Bulk grains are inspected prior to delivery to ensure they meet our high standards. Vitamin/mineral premixes and other additives are purchased.

Grinding: Whole grains are processed through a hammer mill before inclusion in pelletised products. This reduces the particle size of the grain for optimum pellet quality, digestibility, and nutritional value.

Warehouse & dispatch: Thompson and Redwood maintain low stock holdings of all of our products. We manufacture almost our entire range of products on a weekly basis, so you can be sure that the product you get is as fresh as can be.

Batching: Our computer controlled batching system ensures accurate addition of ingredients to maintain the quality and consistency of the finished product. Records are maintained for each production batch that show exactly what ingredients were used and when it was made.[/vc_column_text][/vc_column_inner][/vc_row_inner][vc_single_image image=”1289″ img_size=”medium” alignment=”center” css=”.vc_custom_1473235079978{background-color: #efefef !important;}”][/vc_column][vc_column width=”1/2″ css=”.vc_custom_1520935136743{margin-left: 3px !important;background-color: #efefef !important;}”][vc_column_text css=”.vc_custom_1516693240852{background-color: #efefef !important;}”]Grain Cleaning: Each whole grain that we bag and sell is processed through a cleaning system to remove any unwanted foreign matter (such as stalk or husk) from the grain.

Pelleting: After grinding and mixing, the pelleting process turns the loose mash mixture into individual pellets. Each pellet contains all of the ingredients of the batch and will not separate back out in transport or feeding systems. The pelleting process also improves the digestibility of the ingredients. The pellets are heavier than the individual components, meaning that more can be transported at one time and thus reducing transportation costs.

Steam Rolling and Muesli: Our range of steam rolled grains are further cleaned and bagged before sale. The steam rolling process improves the digestibility and palatability of the grain, making it tastier and healthier for your animal! Our steam rolled grains are also mixed with other seeds and fibre sources plus molasses and oil to create a range of highly nutritious and great tasting muesli products.[/vc_column_text][/vc_column][/vc_row]